Auto parts mould

Automotive Parts & Mold Manufacturing Capabilities, World-class advanced High accuracy equipment that can achieve an accuracy tolerance of 0.005.

Get a quote

LiSong is a professional plastic injection mold manufacturer. With 20,000 square meters of factory and more than 10 years of export experience. The main exporting countries are Australia, USA, Canada, etc. We export more than 1000 containers to the world every year.

Explore our Products range and contact us today.

(Get 20% Off Now)

Lisong produce a variety of plastic injection mold, including plastic PET preform mould, bottle cap mould, PVC pipe fitting mould, chair mould, paint bucket mould, thin wall mould, dustbin mould, box mould, commodity mould, automotive mould,logistics and packaging mould, medical consumable mould, etc.

Lisong also can customize injection mold according to the size and shape required by the customer.

Focus on manufacturing mould for 10 years With 20000sqm Factory and 2 production line; 10 years warranty;

The following examples are only a small selection of products, for more detailed examples please contact us.

Automotive Parts & Mold Manufacturing Capabilities, World-class advanced High accuracy equipment that can achieve an accuracy tolerance of 0.005.

Only focus on preform mold ! High quality and high effiency of multi-cavity preform mold. Chinese preform mold manufacturer at high precision for all kinds of injection machine.

Cube Inserted high speed bucket mold with fast cycle, bucket molds and molding machine. Get paint pail mold, come to LiSong Mould for fast delivery and professional solution.

High-quality PVC pipe fitting mold, PVC pipe fittings production equipment, PVC pipe fitting molding line. Design 45° lateral, tees, and other shapes of PVC pipe fitting mold for you.

Producing a series of thin-wall moulds. Include spoon,fork and knife mould;thin-walled container mould; fast food box mould;thin wall bowl mould andother disposable thin wall moulds.

Custom plastic mold, who made lots of plastic molding toys and silicone toys for toy companies, such as custom plastic building blocks toys, car molding toys, train mold toys, Etc

ISO13485:2016 certificated Focusing on developing, design and manufacturing plastic injection molds for disposable medical components, medical devices and laboratory products.

High Quality Household Plastic Injection Mould Washbowl Basin Mould For Washroom Or Kitchen - Buy Moulds,Inject Mold,Basin Mould Product.

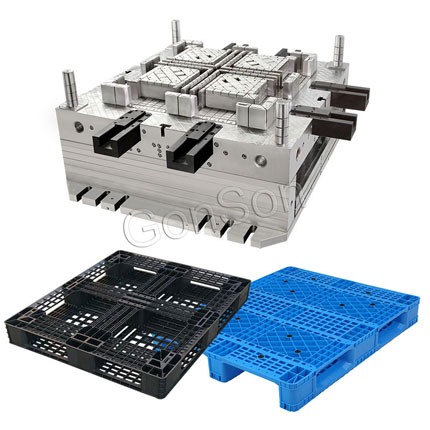

Pallet, double face pallet and various pallet molds with fast divery and good price. Pallet mold solution with High Quality and Competitive Price.Contact us to learn more.

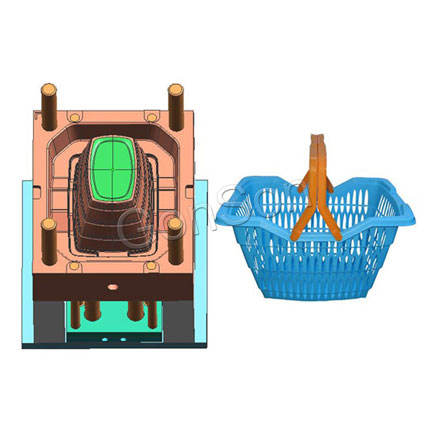

Plastic Injection Mold Tooling for sale, Quality plastic basket mold on sale of MOLD&MORE from China.

Offers the comprehensive solution for quality plastic injection chair moulds, mail us now! Complete support: plastic chair concept design, chair mold design.

Injection Molding Table, Injection Molding Bench. The most significant advantage of the injection molding table is that it saves you time during mold changes.

Our factories mold products include common custom plastic molds, high precision molds.our major product is plastic injection mold,silicone rubbler product and double injection mold.

Lisong supply a variety of plastic crate mould, including: vegetable crate mould, fruit crate mould; logistics box mould, etc

We produce a variety of plastic cap moulds, including flip-top cap mould, water cap mould, Juice cap mould, spray cap mould which could suit for different bottle size.

A: We believe "Quality is above everything". We have professional team to control the quality. Our QC team mainly do the following procedures:

A) Design Optimize control

B) Mould steel hardness Inspection

C) Mould assembly Inspection

D) Mould trial report and samples Inspection

E) Final inspection for mould & packing before shipmentIf you have another question, pls feel free to contact us.

A:Yes.

DWG, DXF, STEP, IGS and X_T files can all be used to quote price, make mould as per your models - This can save time and money in producing your parts.

A: Plastic Materials selection depends on the application of your product.

We will give you some suggestion after we checked the function of your component. And we can make the mould trial with different material according to your requirement.

A: We can make all kinds of plastic injection moulds and blow moulds.

We can suggest you the proper cavity number as per your injection machines sizes.

A: By T/T, L/C, Trade Assurance, Western Union.

A: It takes 6-10 weeks to have the mould manufactured depending on the mould structure and the number of cavity (single or multi) after you approved our mould drawing. The delivery time should be calculated from the date you approved our mould drawing. We can ship your plastic moulds with 1 week after you confirmed our final samples.